Authorized Metrology center and Calibration of flow meters

MATTECH, s.r.o. has been providing metrological services at a professional level for a long time, including verification of flow meters in the Czech and Slovak Republics in this Authorised Metrology Centre K65, calibration of flow meters with throttling devices and metrological service.

The Czech Republic - Verification of the mass flow meters with carrier fluid, liquid, gas and heat meters

- Centric orifice plates, nozzles, Venturi tubes

- Multi-hole (conditioning) orifice plates

- Segmental orifice plates

- Conical inlet orifice plates

The Slovak Republic - Verification of the steam mass flow meters

- Centric orifice plates, nozzles, Venturi tubes

- Multi-hole (conditioning) orifice plates

Metrological service

After assessment of technical and personnel competence of MATTECH, s.r.o. the Czech Metrology Institute issued for the company the Certificate of Registration for the installation and servicing of billing flow meters (heat meters, gas mass flown through them and their devices).

Calibration of Flow Meters with Throttling Devices

In our laboratory we calibrate the throttling devices by indirect geometric control in accordance with EN ISO 5167-1 to 5, ISO/TR 15377, ČSN 25 7711 and others for the flow meters shipped worldwide.

As a Part of the Metrological Service in accordance with Technical Metrological Regulations TPM 3723-03 a TPM 6892-95 we also provide:

- Issuing of assembly sheets with the designation of used heat meters and their ranges for combined meters

- Functional test of compact meters

- Metrological test of the whole unit for combined meters

- Shortened metrological test procedure of gas volume calculator (calorimeter) with orifice plate, including issuance of a protocol

- Securing the meters with mounting seals

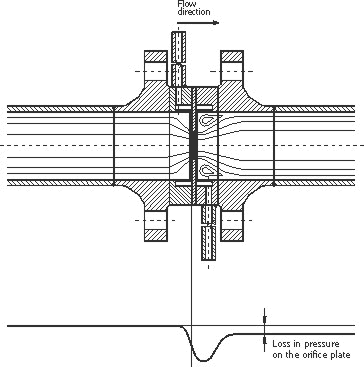

Principle of Measurement

Orifice plates, nozzles and Venturi tubes are designed for measurement of superheated or saturated steam, fluids or gaseous mixtures. The method of measurement is based on pressure differences, so-called pressure differential, which arise during the flow of measured medium through tapering section. Immediate fluid flow is (except for small non-linearity) proportional to root of differential pressure.

The pressure differences are conversed into electric signal in the pressure differential device. This signal is processed in the evaluation unit or in the superiority system together with the temperature and pressure data in the real time. This method of measurement provides results of volume, event. energy of the medium flow.

Calculation of the measurement resides in the solution of Bernoulli equation and the equation of flow continuity and in equations determined on basis of experimental measurement.

Orifice plates, nozzles and Venturi tubes represent unambiguously defined (by the standard) and perfect design of mechanical flow meter without moving parts, that can be used for the measurement of any fluids or gases when maintaining conditions of a single-phase and homogenous flow. MATTECH s.r.o. is due to its specialization a unique manufacturing company, that revived measurement by mechanical flow meters after 1992 and during its 24 years of existence it has produced more than 12, 000 pieces of orifice plates, nozzles and Venturi tubes both for home market and for export to every corner of the world – from North to South – from extraction of natural gas beyond the Arctic Circle up to the measurement of steam flow in a solar power plant in the desert. From East to West, from orifice plates supplies to oil fields in the Gulf of Mexico to supplies of nozzles for power plant units in Asia. Compared to electronic flow meters of the competitors throttling devices by MATTECH are the most reliable types of flow meters with long service life due to designs proved in decades. Their service life is often beyond the lifetime of connection pipes. Uncertainty of the orifice plates is often fully comparable to any electronic competition, and if these are calibrated by wet method at the test room (by fluid or gas), even though it is beyond the standard requirement, then the orifice plate, nozzle and Venturi tube, that are precisely manufactured, achieve higher accuracies than it is stated in the standard. Favourable purchase and operating costs of measurements with orifice plates, that is maintenance-free and without need of spare parts, are other benefits for our clients.